How Do RTD Sensors Work?

This article will focus on discussing one of our products for thermal protection, the RTD Sensors.

What is an RTD?

RTD sensors or resistance temperature detectors are temperature sensors that measure temperature based on the changes of resistance of metal with temperature. They are also referred to as resistance thermometers. They have sensing elements placed near the area at which the temperature must be measured. They are most used in industrial applications because of their accuracy, repeatability, and ability to withstand harsh environments.

Major Components of RTD Sensors

- A resistance element is a metal that senses temperature changes. Its length usually ranges from ⅛” to 3”. In most cases, it is platinum because platinum is chemically inert, offers almost linear temperature-resistance relationships, and can sense resistance changes quickly. Other materials used as resistance elements are copper, nickel, iridium, tungsten, and Balco.

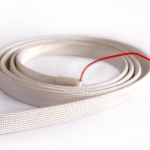

- Wires connect the resistance element to the measuring instrument. The number of wires connecting the resistance element to the measuring instrument varies for different applications. RTD sensors with more wires are known to be more accurate. Two-wire RTD sensors are generally used for applications where approximate temperature values are needed, whereas three-wire RTD sensors are most commonly used in industrial applications. Four-wire RTD sensors are the most accurate of the three-wire configurations of RTD sensors and are used in applications where tougher temperature control is required. For protection, these wires are insulated with Teflon or fiberglass.

- Tubing materials commonly used for industrial assemblies are stainless steel 316 and Inconel. Stainless steel 316 is suitable for assemblies up to 500 °F. Beyond 500 °F, Inconel 600 is used for tubing materials.

- Process connections include standard fittings for thermocouples such as compression, welded, and spring-loaded fittings.

- The outer diameter of an RTD is located just above the resistance element. It ranges from 0.063” to 0.500”.

- Cold end termination of RTD sensors can be plugs, bare wires, terminal heads, or reference junctions common to thermocouples.

Working Principle of RTD Sensors

RTD sensors are commonly covered with stainless steel or Inconel that protects the sensing element from shocks, vibrations, and other mechanical impacts. These allow them to be placed directly to the area where temperature must be measured. The size and lengths of connecting wires affect temperature readings. Thus, all connecting wires should have similar sizes and lengths to ensure good calibration. The calibration of an RTD sensor is carried out by comparing its resistance values against a standard. On the other hand, the frequency of calibration of RTD sensors depends on the temperature cycle and the environmental and mechanical impacts affecting the RTD sensors.

The working principle of RTD sensors is based on the correlation between metal resistance and temperature. During operations, electric current is transmitted through a piece of metal or the resistance element. Using the metal’s known resistance characteristics, the measured resistance value of the resistance element is then correlated to temperature. The metal resistance to the flow of current increases as the temperature of the metal increases. Electrical resistance is usually expressed in ohms, and resistance elements are commonly specified based on their resistance in ohms at 0 °C.

Applications of RTD Sensors

RTD sensors provide consistent, reliable, and accurate temperature measurements, making them suitable for a wide range of industrial applications. They are used in the automotive industry to measure engine, air, and water temperatures. They are also found in pharmaceutical, chemical, and electronics industries where temperature monitoring and control are of utmost importance. RTD sensors have countless applications. This is all because of their adaptability, flexibility, and reliable performance.

Mec supplies a wide selection of quality electric motor parts, vibration and thermal sensors, and accessories. Since 2004, we have been providing top-quality, customized sensors for our customers.

For more questions about RTD sensors, do not hesitate to contact us!

Author:

John Hamlin

About the Author

John Hamlin is a freelance writer who has a background in engineering. With a keen interest in technology and writing, John has been working online providing insight and direction for many years. His latest work has been on a compilation of industrial manufacturing techniques.